Superalloy InconelX-750/ UNS N07750/ AlloyX-750 Pipe isina musono, Sheet, Waya

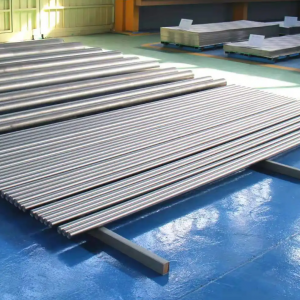

Available Products

Seamless chubhu, Plate, tsvimbo, Forgings, Fasteners, Pipe Fittings

Mamiriro Okugadzira

| Product | ASTM |

| Mabhawa uye Forgings | B 637 |

Kuumbwa Kwemakemikari

| % | Ni | Cr | Fe | C | Mn | Si | S | Ti | Nb+Ta | Al | Co | Cu |

| Min | 70.0

| 14.0 | 5.0 |

|

|

|

| 2.25 | 0.70 | 0.40 |

|

|

| Max | 17.0 | 9.0 | 0.08 | 1.00 | 0.50 | 0.010 | 2.75 | 1.20 | 1.00 | 1.00 | 0.50 |

Zvinhu Zvenyama

| Density | 8.28 g/cm3 |

| Melting | 1393-1427℃ |

Inconel X-750 Zvimiro

Inconel X-750 alloy inonyanya kuita nickel-based superalloy iyo inosimbiswa nezera ne γ[Ni3(Al, Ti, Nb)] chikamu.Iyo ine yakanaka corrosion resistance uye oxidation resistance pazasi 980 ℃, uye pazasi 800 ℃ Iine high corrosion resistance.Iine kuzorora kwakanaka kwekudzivirira pazasi 540 ° C, pamwe nekuumbwa kwakanaka uye weldability.Alloy iyi inonyanya kushandiswa kugadzira injini dzendege dzinoshanda pasi pe800°C uye dzinoda simba guru..Zvitubu zvinogona zvakare kushandiswa kugadzira steam turbine turbine blades uye zvimwe zvikamu, senge mahwendefa, mitsetse, mabara, forging, mhete, waya, mapaipi, nezvimwe.

Inconel X-750 Heat Treatment Process

Iyo mhinduro yekupisa kupisa system yemaplate, mitsetse uye mapaipi munzvimbo yekugovera ndeye 980 ℃ ± 15 ℃, kutonhora kwemhepo.Kune yepakati yekupisa yekurapa system yezvinhu uye zvikamu, zvinotevera maitiro anogona kusarudzwa kurapwa kwekupisa.

Annealing: 955~1010 ℃, kutonhora kwemvura.

Kusungirirwa kwezvikamu zvakakanyiwa zvisati zvakuchidzira: 980 ℃, 1h.

Kushushikana kwekunetseka kusungirirwa kwezvikamu zvakasungwa: 900 ℃, kunyorovesa kwe2h.

Kushushikana kwekunetseka annealing: 885 ℃ ± 15 ℃, 24h, kutonhora kwemhepo.

Inconel X-750 Inowanikwa Mhando uye Zvakatsanangurwa

Mabhawa, forgings, mhete, mashizha anopisa-akaputirwa, mashizha anotonhora-akaputirwa, mitsetse, machubhu uye waya zvinogona kupihwa muhukuru hwakasiyana.

Ndiro nemachira anowanzo kupihwa mushure mekupisa kana kutonhora kukungurutswa, annealing kana mhinduro, pickling uye polishing.

Mabhawa, forgings uye zvindori zvinogona kupihwa mune yakaumbwa kana inopisa yakatenderedzwa nyika;ivo vanogona zvakare kupihwa mune mhinduro kurapwa mushure mekugadzira;mabara anogona kupihwa mushure memhinduro uye kukwenenzverwa kana kushandurwa, uye anogona kupihwa mukutonhora kana odha ichida Pull state munzvimbo.

Iyo waya inogona kupihwa mune yakasimba mhinduro mamiriro;kune waya ine dhayamita yezita kana ukobvu pasi pe6.35mm, inogona kuve yakasimba mhinduro uye inopihwa inotonhora yekudhirowa deformation ye50% kusvika 65%;iyo dhayamita yezita kana kureba kwedivi yakakura kupfuura 6.35mm.Wire, mushure mekugadziriswa kwekugadzirisa, inopihwa nekutonhora-kudhirowa deformation isingasviki 30%.Kune waya dzine dhayamita rezita kana kureba kudivi risingapfuuri 0.65mm, dzinogona kupihwa nekutonhora-kudhirowa deformation isingasviki 15% mushure mekugadzirisa mhinduro sezvinodiwa.

Inconel X-750 Nzvimbo dzekushandisa

Iyo alloy inonyanya kushandiswa kugadzira zvitubu zvemashizha uye zvitubu zvemakoiri zvine simba rakawanda rinodiwa uye kuramba kuzorora kwemainjini aero-anoshanda ari pasi pe800 ° C.Inogona zvakare kushandiswa kugadzira zvikamu zvakaita sematurbine blades.Mhando dziripo ndedzepepa, strip, bar, forging, ring, waya nechubhu.